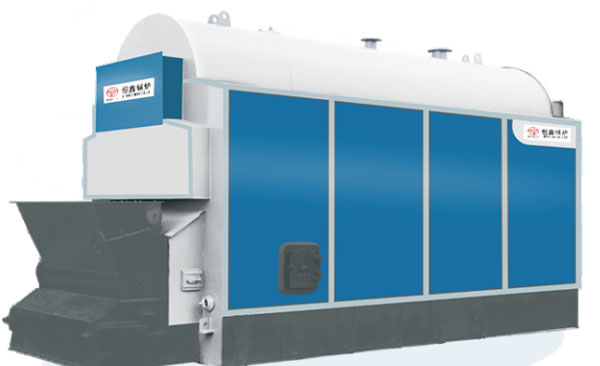

DZH series moving grate biomass fired boiler,which isdeveloped by Yongxing in response to environmentalprotection policy,is a new single-drum horizontal type boiler.Ituses biomass pellets processed from crop waste such as straw,sawdust and peanut shells as fuel.The emission of sulfide influe gas is much less than that of coal-fired boiler,whichmeets the national environmental protection standards.Thecrop waste can be got everywhere,not only changing wasteinto treasure and realizing the reuse of energy,but alsoachieving the dual unity of social and economic benefits withlaw cost,

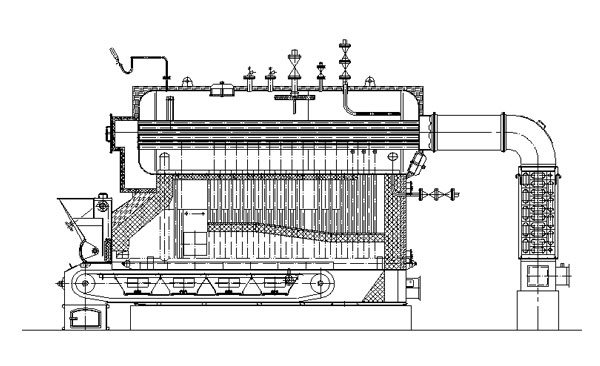

It is horizontal three-returns water-fire tube boiler with a newfurnace design,which greatly promotes fuel combustion andachieve the thermal efficiency to 83%.After fuel combustion,the flue gas enters the dust remover through the hot surface,economizer,air preheater,etc.,and finally is discharged intothe atmosphere through the chimney.The remaining smallamount of ash after burning falls into the slag discharge holeas farmyard fertilizer.

Steam Boiler

| Model Unit | Rated Steam Capacity (t/h) | Rated Working Pressure (MPa) | Saturated Steam Temperature(℃) | Heat Efficiency (%) | Design Fuel | Max Transport Weight (Kg) | Max Transport Dimension L*W*H (mm) |

| DZH0.5-1.25-SCIII | 0.5 | 1.25 | 194 | ≥83% | Coal Biomass Fuel | 9000 | 3300*2000*2656 |

| DZH1-1.25-SCIII | 1 | 13000 | 4500*1800*2800 | ||||

| DZH2-1.25-SCIII | 2 | 21000 | 4900*1900*3255 | ||||

| DZH3-1.25-SCIII | 3 | 23000 | 5200*2000*3300 | ||||

| DZH4-1.25-SCIII | 4 | 24500 | 5830*2150*3480 | ||||

| DZH6-1.25-SCIII | 6 | 26000 | 7740*3770*3440 |

With 40 years of factory history,660,000 square meters of factory area,580 million total assets,500 +service team etc.hengxin Boiler guarantees the real interests of customersthrough national safety and quality inspection institutions at all levels.

With 336 production equipments and more than 300 production models,hengxin devotes itself to scientific and technological innovation and iscommitted to providing customers with the most energy-saving and efficientboiler equipment,and each boiler is directly exported by hengxin manufacturers,with higher cost-effective performance in the boiler market.

hengxin Boiler adopts the latest intelligent boiler cloud platform system,realizes the overall control of the boiler operation state,and truly realizes worry-free ideal state.

hengxin Boiler,as a high-tech boiler manufacturer,is dedicated to making boilerswith services of R&D innovation,design customization,production specialization,sales refinement,installation standardization,renovation proficiency,EPC project comprehensiveness.

Technical consultation in 30 minutes,clear plan in 2 hours,dispatchof engineers at home and abroad in 24-72 hours,free maintenancewithin 12 months since shipment.

Some products are available in stock.Boilers under 15 tons can be delivered in 15 days,boilers with 15-25 tons can be delivered in 20 days andboilers with 25 tons or more can be delivered in 35 days.