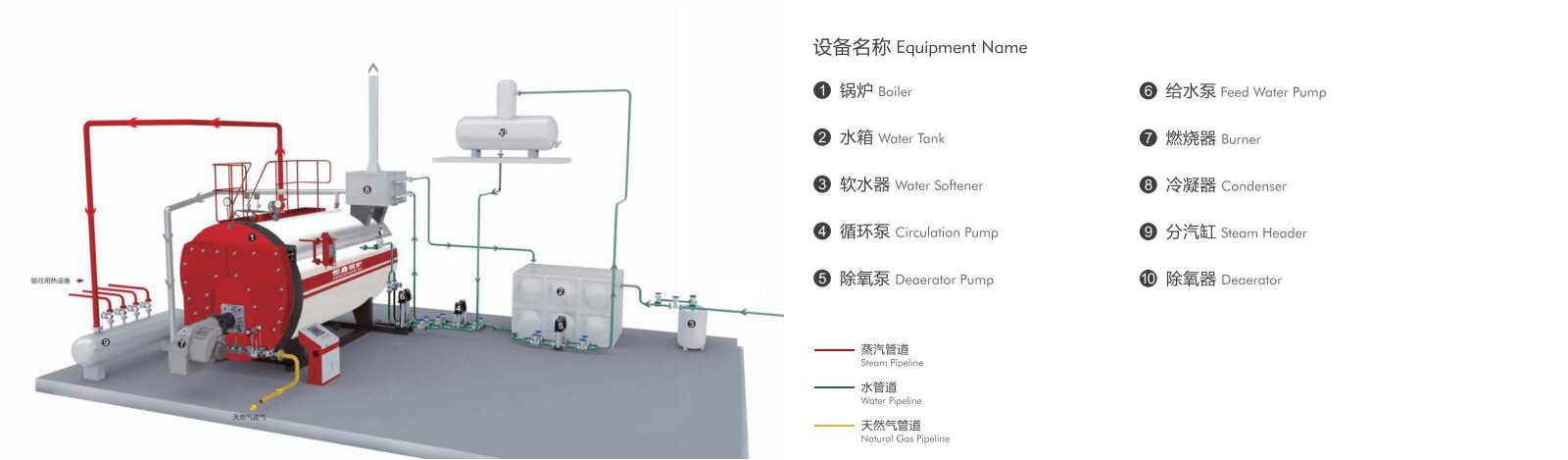

Under the national policy of promoting environmental protectionand eneray conservation,based on vears of experience in boilerR&D and manufacturing,hengxin produces NWNS integratedcondensina boilers.Its surface is eguipped with intearatedcondenser,which can decreose the exhaust temperature of theboiler to 60-80°C,and absorbs part of the heat from flue gas,greatly improve the thermal efficiency of the boiler to more than 100.2%.Same time,it greatly reduces harmful gasesdischarae and enwironmental pollution under heat recoveryprocessing.With characteristics of energy-efficient andenvironmentally fiendw.it is widelv used in food,apparel,textile.petrochemical and machinery manufacturing industries.

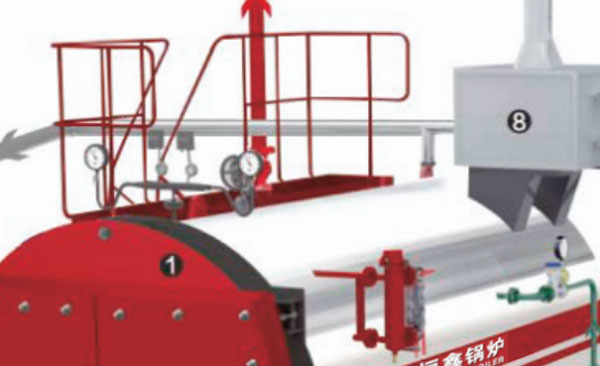

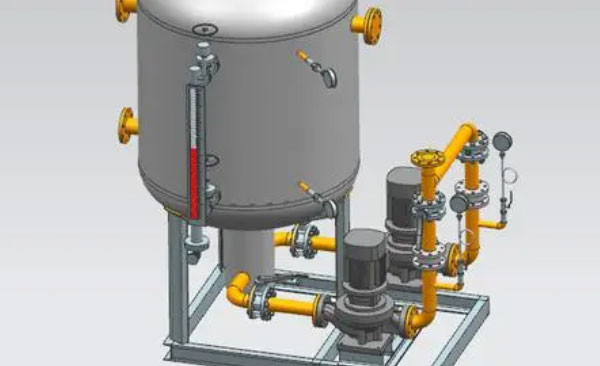

NWNS intearated condensing boiler is mainly composed of boilerbody,burner,instruments,connecting flue,condenser,water tank,feed water pump,steam heoder,deoerotor,circulating pump,water softener,etc.With the features of clean combustion,pollution-free emission,convenient operation,sufficient output,sufficient combustion and high thermal efficiency,it is the mosteneray-savina,hiah-efficiencv,enwironmentally-friendly and idealheatina device boiler product in recent years,

Steam Boiler

| Model unit | NWNS1-1.25-YQ | NWNS2-1.25-YQ | NWNS3-1.25-YQ | NWNS4-1.25-YQ | NWNS6-1.25-YQ | NWNS8-1.25-YQ | NWNS10-1.25-YQ | NWNS12-1.25-YQ | NWNS15-1.25-YQ | NWNS20-1.25-YQ |

| Rated Steam Capacity (t/h) | 1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| Rated Working Pressure (MPa) | 0.7 | 1.0 | 1.25 | 1.6 | 2.5 | |||||

| Saturated Steam Temperature(℃) | 171 | 184 | 194 | 204 | 225 | |||||

| Boiler thermal efficiency (% ) | 100.2 | |||||||||

| Design Fuel | Natural Gas,Light Oil,Heavy Oil etc. | |||||||||

| Max Transport Weight (Kg) | 4800 | 7500 | 9000 | 12000 | 15198 | 19000 | 24372 | 27500 | 30000 | 39000 |

| Max Transport Dimension L*W*H (mm) | 3400*1900*2200 | 4073*2000*2450 | 4550*2000*3450 | 5200*2300*3300 | 4900*2938*3605 | 6330*2910*3150 | 6860*2808*3168 | 7100*3000*3200 | 7365*3200*3508 | 7800*3650*3960 |

With 40 years of factory history,660,000 square meters of factory area,580 million total assets,500 +service team etc.hengxin Boiler guarantees the real interests of customersthrough national safety and quality inspection institutions at all levels.

With 336 production equipments and more than 300 production models,hengxin devotes itself to scientific and technological innovation and iscommitted to providing customers with the most energy-saving and efficientboiler equipment,and each boiler is directly exported by hengxin manufacturers,with higher cost-effective performance in the boiler market.

hengxin Boiler adopts the latest intelligent boiler cloud platform system,realizes the overall control of the boiler operation state,and truly realizes worry-free ideal state.

hengxin Boiler,as a high-tech boiler manufacturer,is dedicated to making boilerswith services of R&D innovation,design customization,production specialization,sales refinement,installation standardization,renovation proficiency,EPC project comprehensiveness.

Technical consultation in 30 minutes,clear plan in 2 hours,dispatchof engineers at home and abroad in 24-72 hours,free maintenancewithin 12 months since shipment.

Some products are available in stock.Boilers under 15 tons can be delivered in 15 days,boilers with 15-25 tons can be delivered in 20 days andboilers with 25 tons or more can be delivered in 35 days.