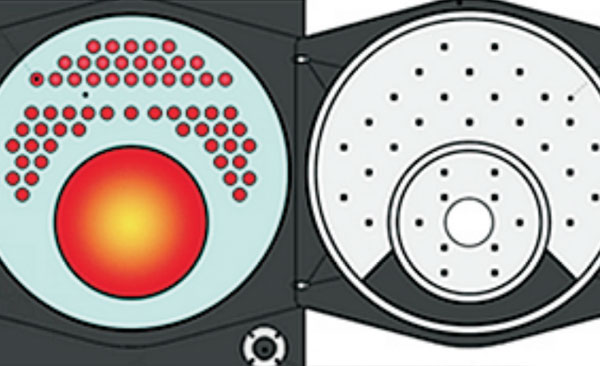

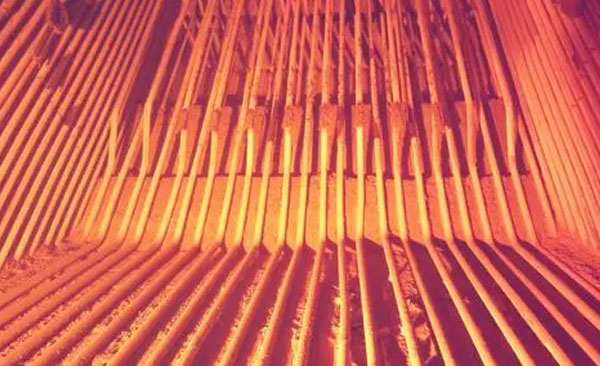

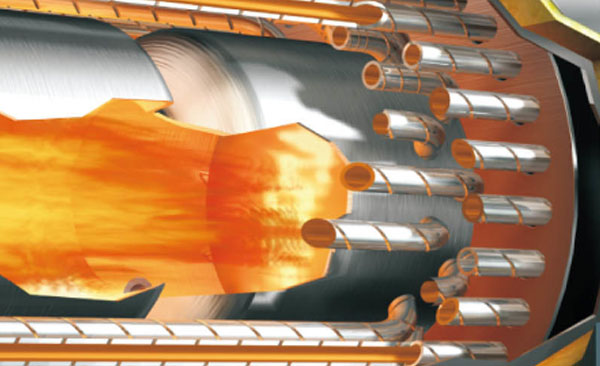

Oil gas atmospheric pressure hot water boiler is also called oil gas non-pressurized hot water boiler, which belongs to the categoryofcivilboilers.Oilgasatmosphericpressurehotwaterboileris akindofnon-pressurizedhotwaterboilerwithairoutletatthetop,and the boiler body is always in the state of atmospheric pressure operation.Itsmaincharacteristicisthattheboilerisnotunderpressure, and there is no safety hazard. It is one of our more common boiler varieties. Atmospheric pressure hot water boilers do not belong to special equipment (boilers), the design, production, installation and use of such boilers are not subject to the supervision of the technical supervision department.Fuel gas efficient hot water boiler adopts horizontal three-return all-wet back structure and threaded heat exchange smoke pipe, environmental protection, economic, reliable; At the same time to meet the high temperature heating while still maintaining high heating power, can increase the efficiency of the system up to 9.5%;P

| Model Unit | Rated Heat Power (MW) | Rated Working Pressure (MPa) | Rated Outlet/Return Temperature(℃) | Nitrogen Oxides (mg/m3) | Design Fuel | Max Transport Weight (Kg) | Max Transport Dimension L*W*H (mm) |

| CWNS0.7-85/60-YQ | 0.7 | Atmospheric pressure | 85/60 | 18-30 | Natural Gas,Light Oil,Heavy Oil etc | 4320 | 3200*1800*2000 |

| CWNS1.4-85/60-YQ | 1.4 | 6300 | 3800*1900*2200 | ||||

| CWNS2.1-85/60-YQ | 2.1 | 8900 | 4100*2000*2400 | ||||

| CWNS2.8-85/60-YQ | 2.8 | 11200 | 4400*2300*2600 | ||||

| CWNS3.5-85/60-YQ | 3.5 | 13200 | 5300*2400*2700 | ||||

| CWNS4.2-85/60-YQ | 4.2 | 14300 | 5600*2500*2800 | ||||

| CWNS5.6-85/60-YQ | 5.6 | 19200 | 6800*2600*3000 | ||||

| CWNS7-85/60-YQ | 7 | 23000 | 6300*2700*3200 | ||||

| CWNS10.5-85/60-YQ | 10.5 | 35500 | 8700*3700*3500 | ||||

| CWNS14-85/60-YQ | 14 | 42600 | 8050*3750*3950 |

With 40 years of factory history,660,000 square meters of factory area,580 million total assets,500 +service team etc.hengxin Boiler guarantees the real interests of customersthrough national safety and quality inspection institutions at all levels.

With 336 production equipments and more than 300 production models,hengxin devotes itself to scientific and technological innovation and iscommitted to providing customers with the most energy-saving and efficientboiler equipment,and each boiler is directly exported by hengxin manufacturers,with higher cost-effective performance in the boiler market.

hengxin Boiler adopts the latest intelligent boiler cloud platform system,realizes the overall control of the boiler operation state,and truly realizes worry-free ideal state.

hengxin Boiler,as a high-tech boiler manufacturer,is dedicated to making boilerswith services of R&D innovation,design customization,production specialization,sales refinement,installation standardization,renovation proficiency,EPC project comprehensiveness.

Technical consultation in 30 minutes,clear plan in 2 hours,dispatchof engineers at home and abroad in 24-72 hours,free maintenancewithin 12 months since shipment.

Some products are available in stock.Boilers under 15 tons can be delivered in 15 days,boilers with 15-25 tons can be delivered in 20 days andboilers with 25 tons or more can be delivered in 35 days.