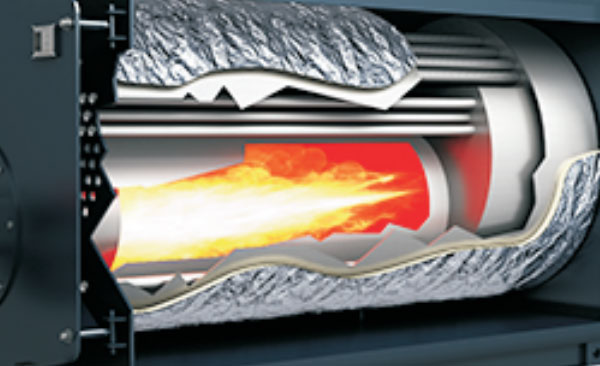

Cross flow boiler "is composed of long pipe design arrangement, feed water pump at one end of the pipe, water (working medium) in the pipe through the heating water section, evaporation section, (overheating section), from the pipe collection box to produce the required steam. Itis differentfrom vertical watertube natural circulation boiler. There is no boiler cylinder, itis composed ofthe boiler body (body up and down the collection box, tube, etc.) and the external water separator, water pump, oil pump, burner and other components. The cross flow boiler has the advantages of compact structure, small occupation of ground, saving steel, large safety factor, high thermal efficiency, small air pollution, and soot emission in line with national standards. Automatic boiler ignition, flameout protection, load regulation, high and low water level control, overpressure protection and other aspects, all realize automatic operation, boiler start-up production is short, only a few minutes boiler can reachtherequiredoperatingload.

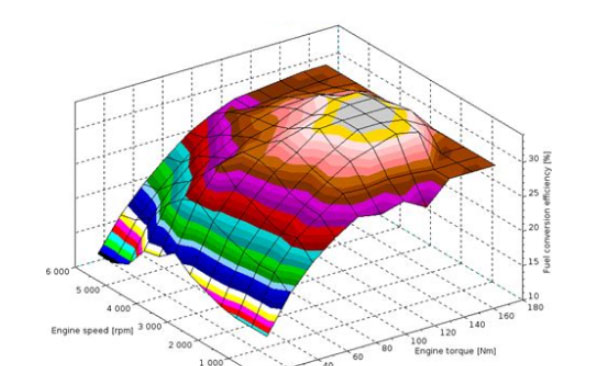

Tachnical parameters of LSS tubular boiler

| Boiler Type | LSS0.5 | LSS1.0 | LSS2.0 | LSS4.0 | |

| Rated Output (t/h) | 0.5 | 1 | 2 | 4 | |

| Rated Steam Pressure (MPa) | 1 | 1 | 1 | 1.6 | |

| Steam Temperature (℃) | 184 | 184 | 184 | 204 | |

| Feod Water Temperature (℃) | 20 | 20 | 20 | 20 | |

| Type Of Burning | Hi Low-Off | Hi Low-Off | Hi Low-Off | Hi Low-Off | |

| Thermal Efficiency(%) | >96.5 | >96.5 | >96.5 | >96.5 | |

| Apply Fue | Diesel oil、Heavyoil、Natural gas | ||||

| Fuel Consumption | Diesel oil (kg/h) | 29 | 58 | 119 | 238 |

| Heavy oil (kg/h) | 31 | 62 | 125 | 249 | |

| Natural gas (Nm3/h) | 36 | 75 | 148 | 296 | |

| Main steam port | DN40 | DN50 | DN65 | DN125 | |

| Feed water inlet | DN20 | DN25 | DN32 | DN40 | |

| Electric Power (kW) | 3 | 8 | 9 | 15 | |

| Chimney Diameter(mm) | φ200 | φ200 | φ430 | φ580 | |

| Size | L(mm) | 2100 | 2300 | 2500 | 3000 |

| W(mm) | 1600 | 2000 | 2300 | 3200 | |

| H(mm) | 2100 | 3000 | 3100 | 4800 | |

With 40 years of factory history,660,000 square meters of factory area,580 million total assets,500 +service team etc.hengxin Boiler guarantees the real interests of customersthrough national safety and quality inspection institutions at all levels.

With 336 production equipments and more than 300 production models,hengxin devotes itself to scientific and technological innovation and iscommitted to providing customers with the most energy-saving and efficientboiler equipment,and each boiler is directly exported by hengxin manufacturers,with higher cost-effective performance in the boiler market.

hengxin Boiler adopts the latest intelligent boiler cloud platform system,realizes the overall control of the boiler operation state,and truly realizes worry-free ideal state.

hengxin Boiler,as a high-tech boiler manufacturer,is dedicated to making boilerswith services of R&D innovation,design customization,production specialization,sales refinement,installation standardization,renovation proficiency,EPC project comprehensiveness.

Technical consultation in 30 minutes,clear plan in 2 hours,dispatchof engineers at home and abroad in 24-72 hours,free maintenancewithin 12 months since shipment.

Some products are available in stock.Boilers under 15 tons can be delivered in 15 days,boilers with 15-25 tons can be delivered in 20 days andboilers with 25 tons or more can be delivered in 35 days.