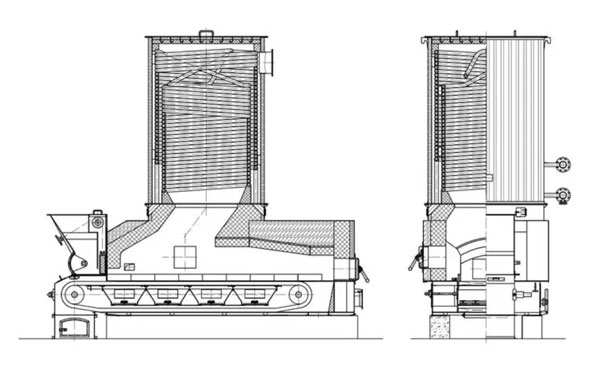

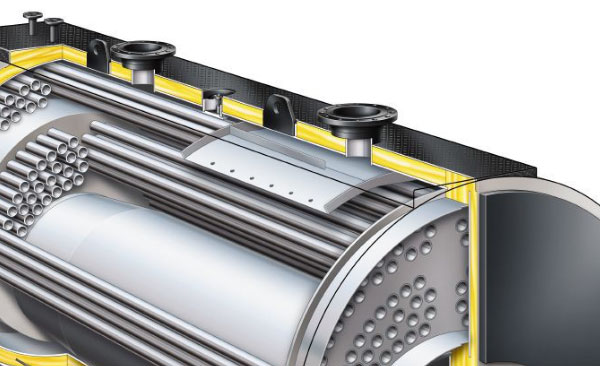

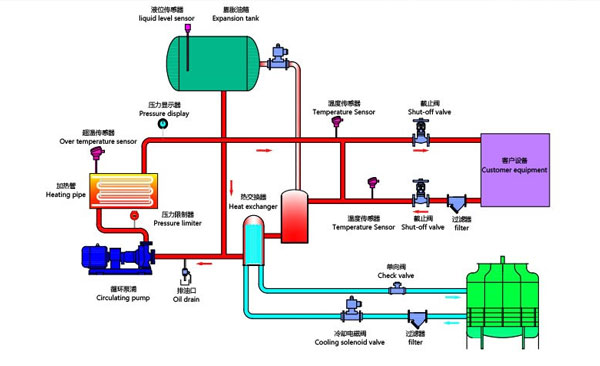

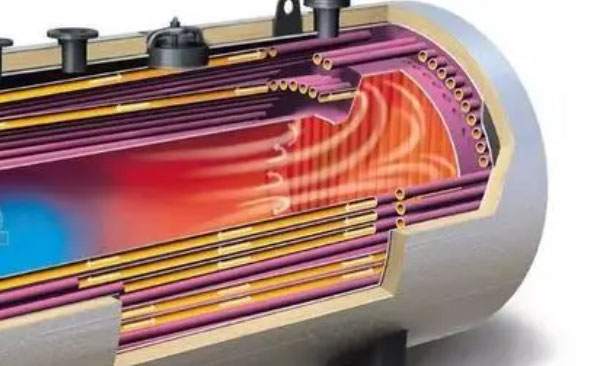

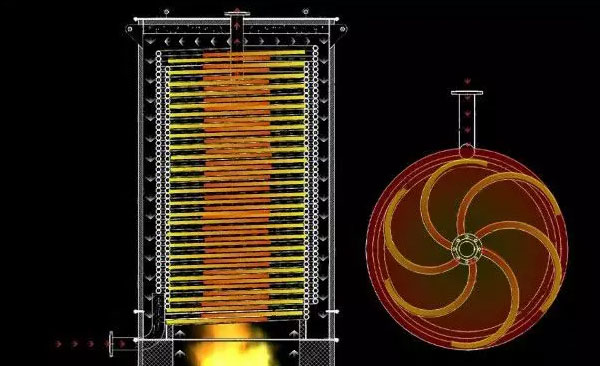

YGL biomass thermal oil heater is a kind of forced circulationvertical biomass boiler that takes biomass particles as fuel andheat conducting oil as medium,using circulation oil pump toforce the circulating oil to conduct the liquid phase circulation,and transfers the heat energy to the heating equipment andretums to the heating furnace for reheating.It is an ideal heatingequipment.Three-retum coil design with sufficient heatingsurfoce and expansion and absorption,realizing low-pressureand high-temperature heating.Also the economizer can beadded to make the boiler more energy saving,which can bemore efficient used in all walks of life.

YGL biomass thermal oil heater prcwided by hengxin BoilerGroup is with low pressure,high temperature performance,better heating temperature up to 340℃ in liquid phase.Therefore,it can be used in worious production situations whererequire unifomm heating without direct flame heating and theheating temperature of 150-380C.Better that,boilers haveadvantoges such as high heat utilization rate,good heot tronsferperformance,safe and reliable operation,perfect protectionfunction,convenient operation and maintenance,etc.,whichhave unparalleled advantoges to other equipment.Therefore,they are not only widely used in all industries,but also exportedto many countries and regions all over the world.

YGL Biomass (coal) Fired Thermal Fluid Heater

| Model Unit | Rated Heat Power (*10kcal/h) | Rated Working Pressure (MPa) | Rated Working Temperature(℃) | Thermal Efficiency (%) | Medium Circulation Rate(m3/h) | Heating Area (㎡) | Design Fuel | Medium Volume In Furnace (m3) | Max Transport Weight (Kg) | Max Transport Dimension L*W*H (mm) |

| YGL-120SCIII | 10 | 0.7/1.0 | 290/320 | ≥83% | 12.5 | 7.3 | Biomass Fuel | 0.06 | 3000 | 840*1608 |

| YGL-240SCIII | 20 | 20 | 16.3 | 0.19 | 3300 | 1250*2080 | ||||

| YGL-350SCIII | 30 | 30 | 22.4 | 0.26 | 3600 | 1350*2050 | ||||

| YGL-500SCIII | 40 | 40 | 30.8 | 0.37 | 4000 | 1450*2300 | ||||

| YGL-700SCIII | 60 | 60 | 44 | 0.5 | 4500 | 1750*2680 | ||||

| YGL-1000SCIII | 80 | 80 | 63.2 | 0.7 | 5100 | 1750*2990 | ||||

| YGL-1200SCIII | 100 | 100 | 71 | 0.8 | 5400 | 2550*3030 | ||||

| YGL-140SCIII | 120 | 140 | 87.6 | 1.05 | 6000 | 2250*3140 |

With 40 years of factory history,660,000 square meters of factory area,580 million total assets,500 +service team etc.hengxin Boiler guarantees the real interests of customersthrough national safety and quality inspection institutions at all levels.

With 336 production equipments and more than 300 production models,hengxin devotes itself to scientific and technological innovation and iscommitted to providing customers with the most energy-saving and efficientboiler equipment,and each boiler is directly exported by hengxin manufacturers,with higher cost-effective performance in the boiler market.

hengxin Boiler adopts the latest intelligent boiler cloud platform system,realizes the overall control of the boiler operation state,and truly realizes worry-free ideal state.

hengxin Boiler,as a high-tech boiler manufacturer,is dedicated to making boilerswith services of R&D innovation,design customization,production specialization,sales refinement,installation standardization,renovation proficiency,EPC project comprehensiveness.

Technical consultation in 30 minutes,clear plan in 2 hours,dispatchof engineers at home and abroad in 24-72 hours,free maintenancewithin 12 months since shipment.

Some products are available in stock.Boilers under 15 tons can be delivered in 15 days,boilers with 15-25 tons can be delivered in 20 days andboilers with 25 tons or more can be delivered in 35 days.