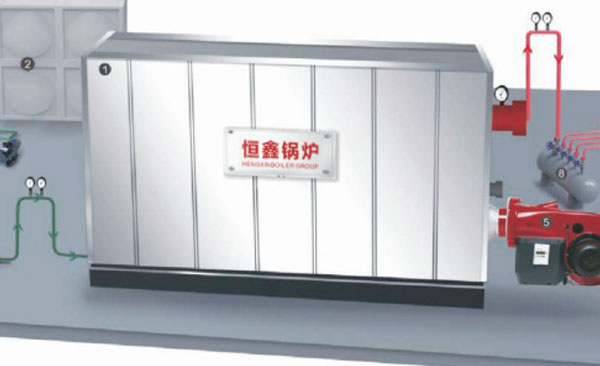

Vacuum hot water boiler forms a closed vacuum environmentinside by pre-vacuume,then filling heat medium water into boiler.It generates negative pressure steam by heating,the heatgenerated by the condensation of negative pressure steam heatsthe cold water in the heat exchange tube,thereby continuouslyproviding hot water to the user.During the operation,the heatmedium water is only enclosed in the vacuum chamber,and heatis transferred between the heat transfer tubes and the heatexchanger.Therefore,the boiler has the characteristics ofconvenient installation,maintenance,environmental protectionand energy saving,and is widely popular in the market.

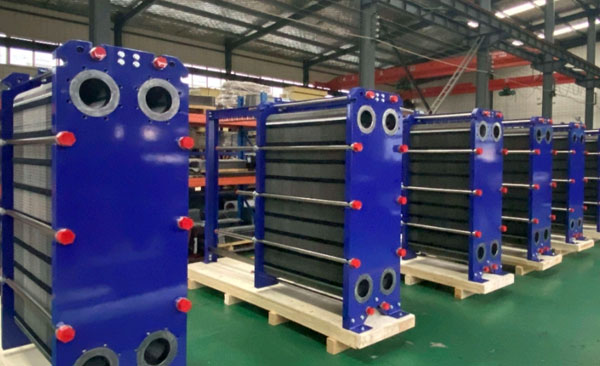

Same with other common boilers,the lower part of vacuum hotwater boiler is composed of a combustion chamber and heattransfer tube.The only difference is that the upper part of thevacuum hot water boiler is vacuum steam chamber,and inside isone U-tube or a straight tube type heat exchange.It is operatedunder negative pressure,so absolutely safe.It can also be usedin many ways,such as providing customers with differenttemperatures and different usage of hot water at the same time,meeting various needs of customers and reduce the cost ofboiler.

| Model Unit | Rated Power (kW) | Adjust Way | Cobustion Way | Design Heat Efficiency(%) | Design Fuel | Max Transport Weight (Kg) | Max Transport Dimension L*W*H (mm) |

| ZWNS30 | 350 | Fully automatic regulation with two-stages fire | Micro-positive pressure chamber combustion | 95.5 | Natural Gas,Light Oil,Heavy Oil etc | 2900 | 3600*1150*1900 |

| ZWNS60 | 700 | 4000 | 4100*1400*2200 | ||||

| ZWNS90 | 1050 | 5300 | 4500*1500*2300 | ||||

| ZWNS120 | 1400 | 6400 | 4800*1600*2400 | ||||

| ZWNS180 | 2100 | 7600 | 5600*1700*2500 | ||||

| ZWNS240 | 2800 | 11000 | 6100*1850*2700 | ||||

| ZWNS300 | 3500 | Fully automatic Ratio Adjustment | Micro-positive pressure chamber combustion | 95.5 | Natural Gas,Light Oil,Heavy Oil etc | 14000 | 6900*1900*2850 |

| ZWNS360 | 4200 | 24000 | 7300*2000*2950 | ||||

| ZWNS480 | 5600 | 30000 | 8000*2150*3050 | ||||

| ZWNS600 | 7000 | 35000 | 8450*2300*3250 | ||||

| ZWNS720 | 8400 | 44000 | 8750*2400*3350 | ||||

| ZWNS900 | 10500 | 51000 | 9150*2400*3350 | ||||

| ZWNS1200 | 14000 | 62000 | 9950*2800*3800 |

With 40 years of factory history,660,000 square meters of factory area,580 million total assets,500 +service team etc.hengxin Boiler guarantees the real interests of customersthrough national safety and quality inspection institutions at all levels.

With 336 production equipments and more than 300 production models,hengxin devotes itself to scientific and technological innovation and iscommitted to providing customers with the most energy-saving and efficientboiler equipment,and each boiler is directly exported by hengxin manufacturers,with higher cost-effective performance in the boiler market.

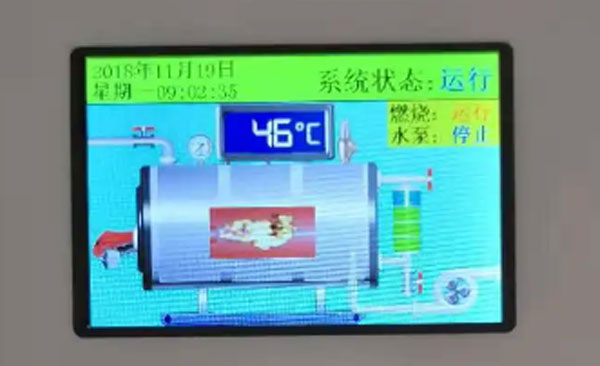

hengxin Boiler adopts the latest intelligent boiler cloud platform system,realizes the overall control of the boiler operation state,and truly realizes worry-free ideal state.

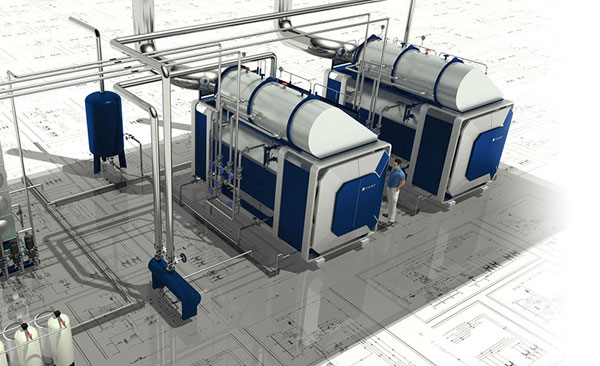

hengxin Boiler,as a high-tech boiler manufacturer,is dedicated to making boilerswith services of R&D innovation,design customization,production specialization,sales refinement,installation standardization,renovation proficiency,EPC project comprehensiveness.

Technical consultation in 30 minutes,clear plan in 2 hours,dispatchof engineers at home and abroad in 24-72 hours,free maintenancewithin 12 months since shipment.

Some products are available in stock.Boilers under 15 tons can be delivered in 15 days,boilers with 15-25 tons can be delivered in 20 days andboilers with 25 tons or more can be delivered in 35 days.